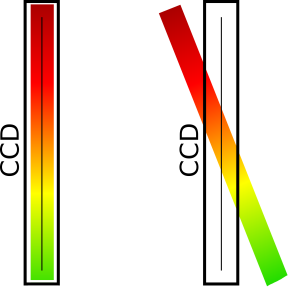

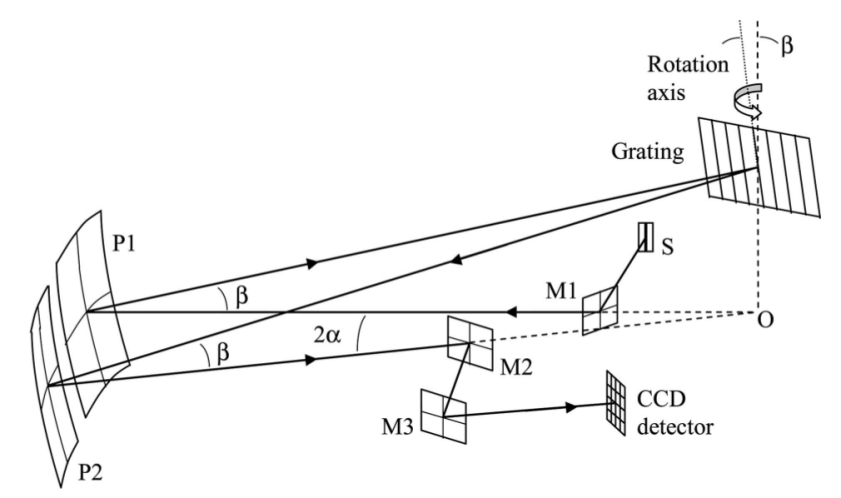

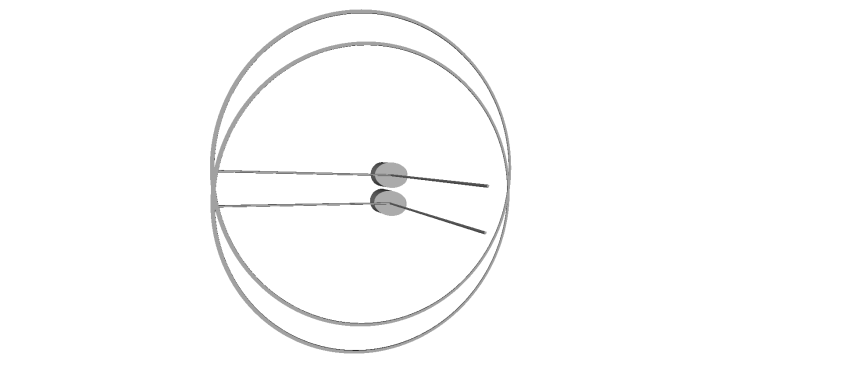

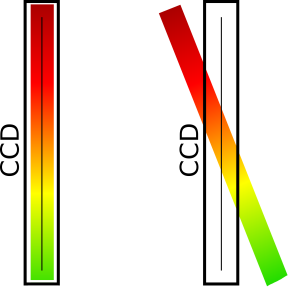

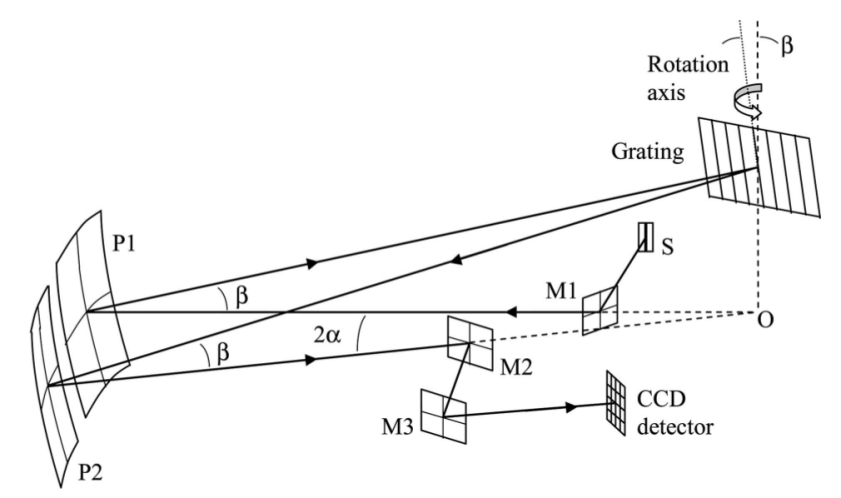

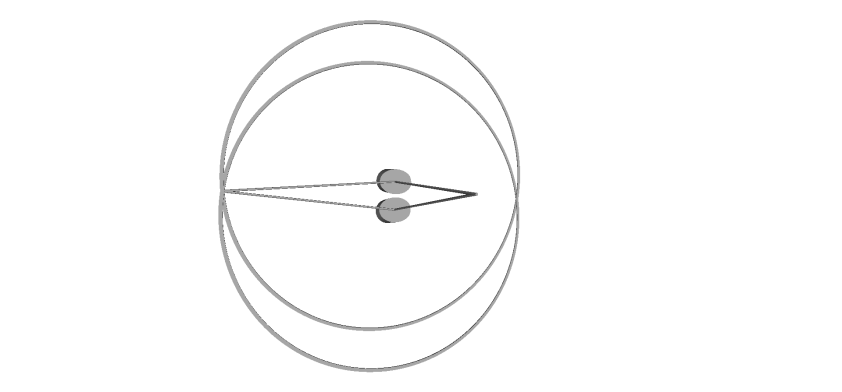

So I’ve been struggling to figure out how to align the mirrors in the spectrograph. The schematic looks like this:

Schieffer et al. APPLIED OPTICS, Vol. 46, No. 16, p 3095-3101

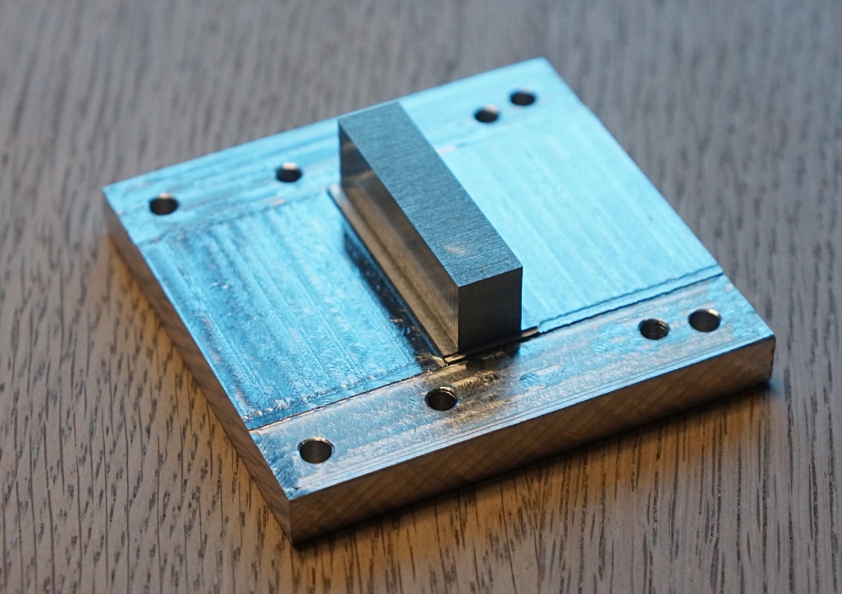

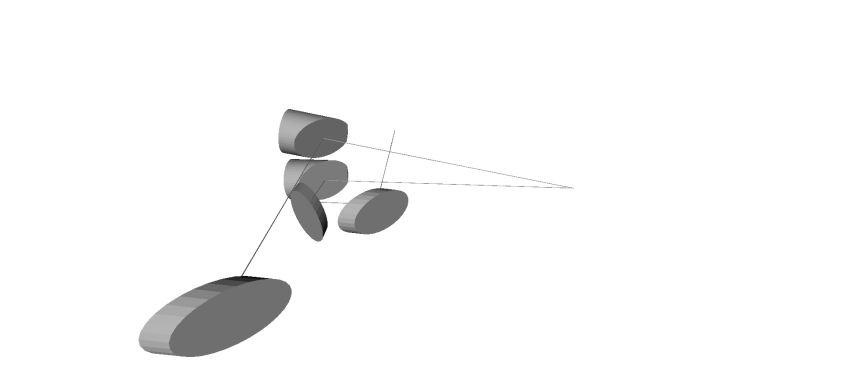

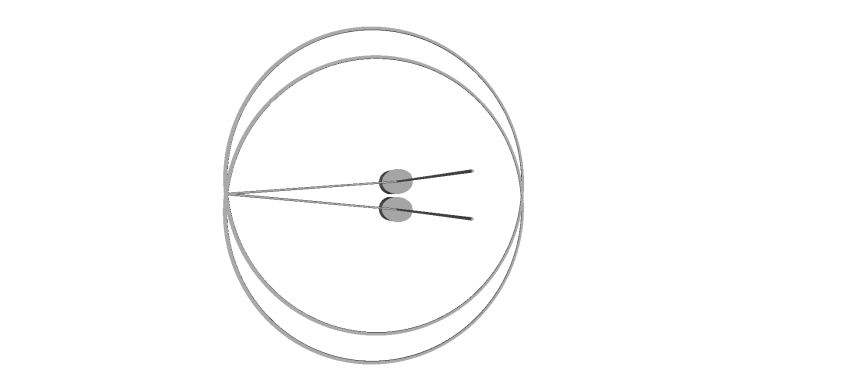

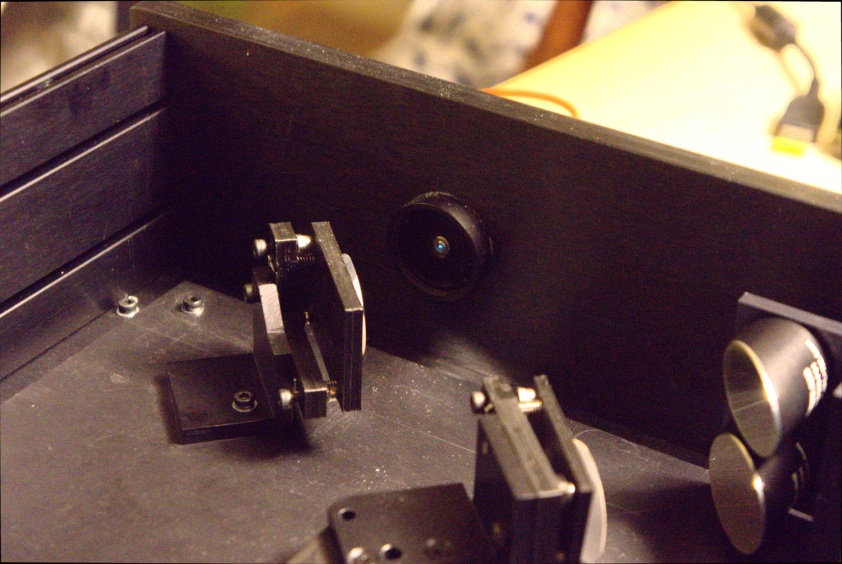

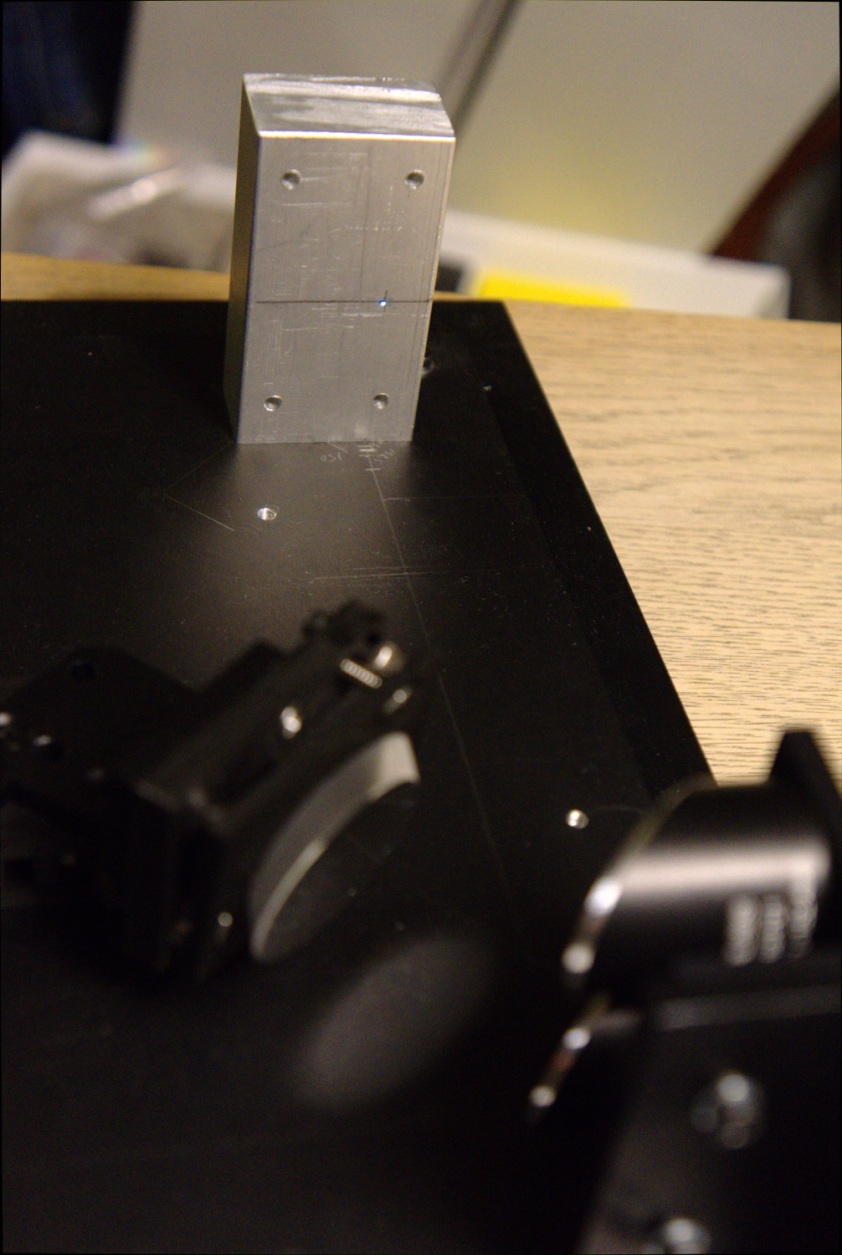

In my spectrograph this translates to:

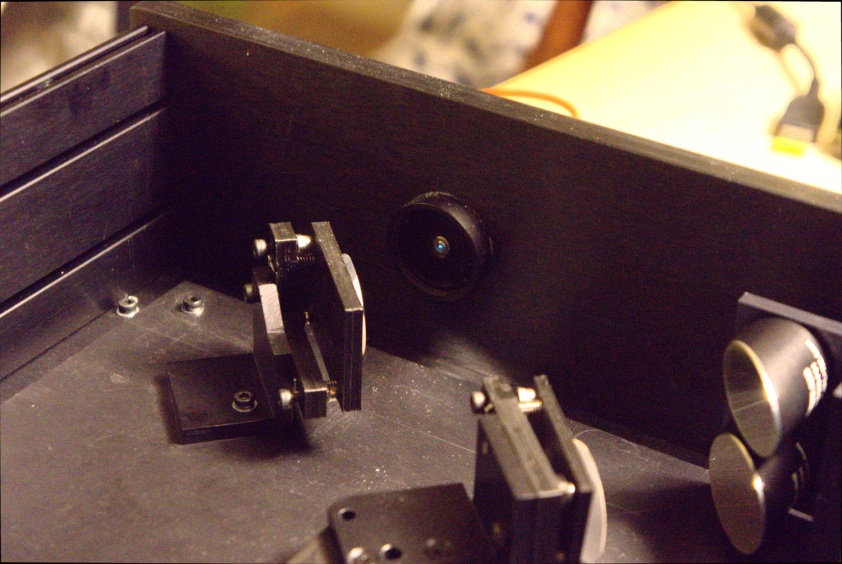

Where P1 and P2 are 152.4 mm 90° off-axis parabolic mirrors (top right). M1, M2 and M3 are elliptical mirrors with an effective diameter of 25.4 mm (M1 is far left, M2 and M3 are in the center). The grating is not shown, but is positioned 152 mm “south” of P1 and P2 (at the end of the pencil line).

According to Schieffer the two parabolic mirrors should be arranged so that the slit is reflected onto itself. This is easier said than done (at least me for it was), as they have rotational freedom around their axis towards the grating, as well as rotational freedom along their off-axis focal point. So where do you start?

Well I started with removing M1 and M2.

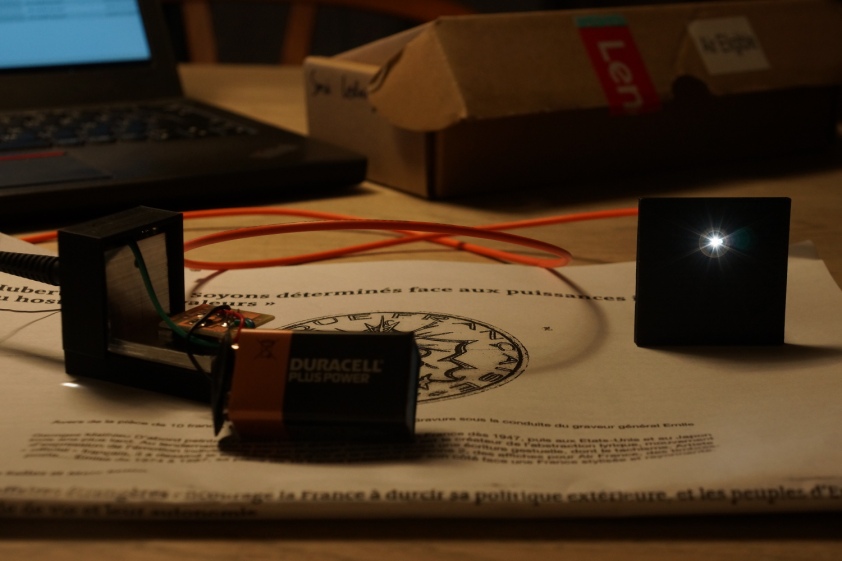

A friend of mine who works at the Niels Bohr institute keeps telling me that 90° angles are my best friends, so I started with that: Having P1 and P2 oriented in horizontally along the aforementioned pencil line. P1 and P3 were then illuminated with an LED torch directed at the mirrors in a horizontal bee-line from the far end of my flat (that’s 7 m, I live in a studio appartment).

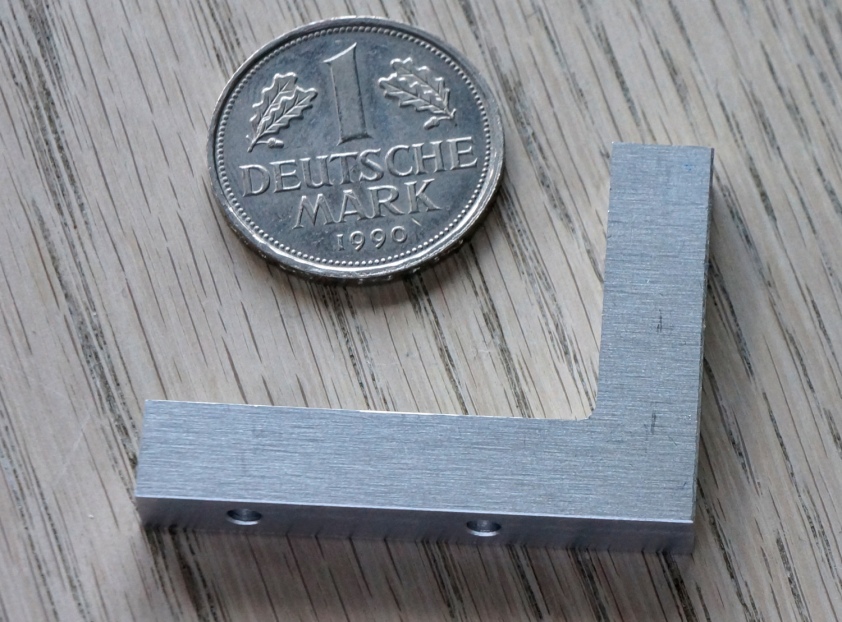

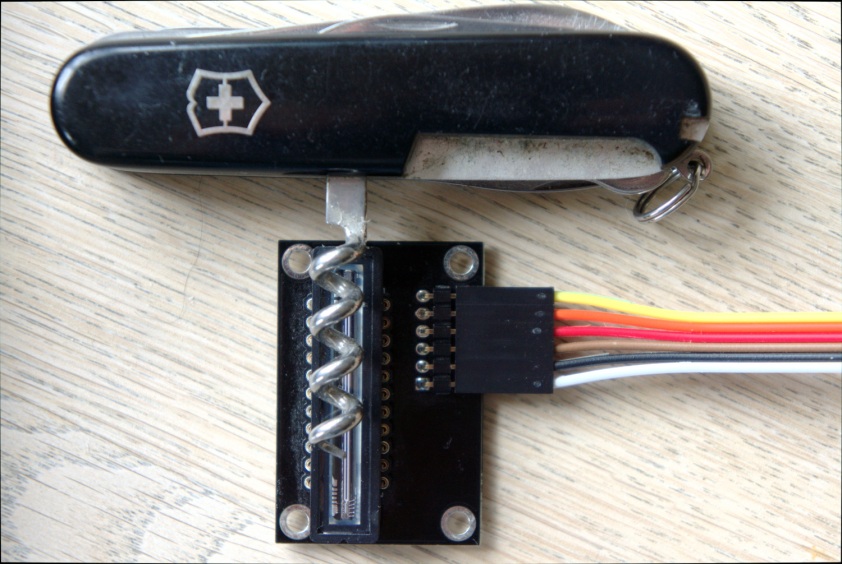

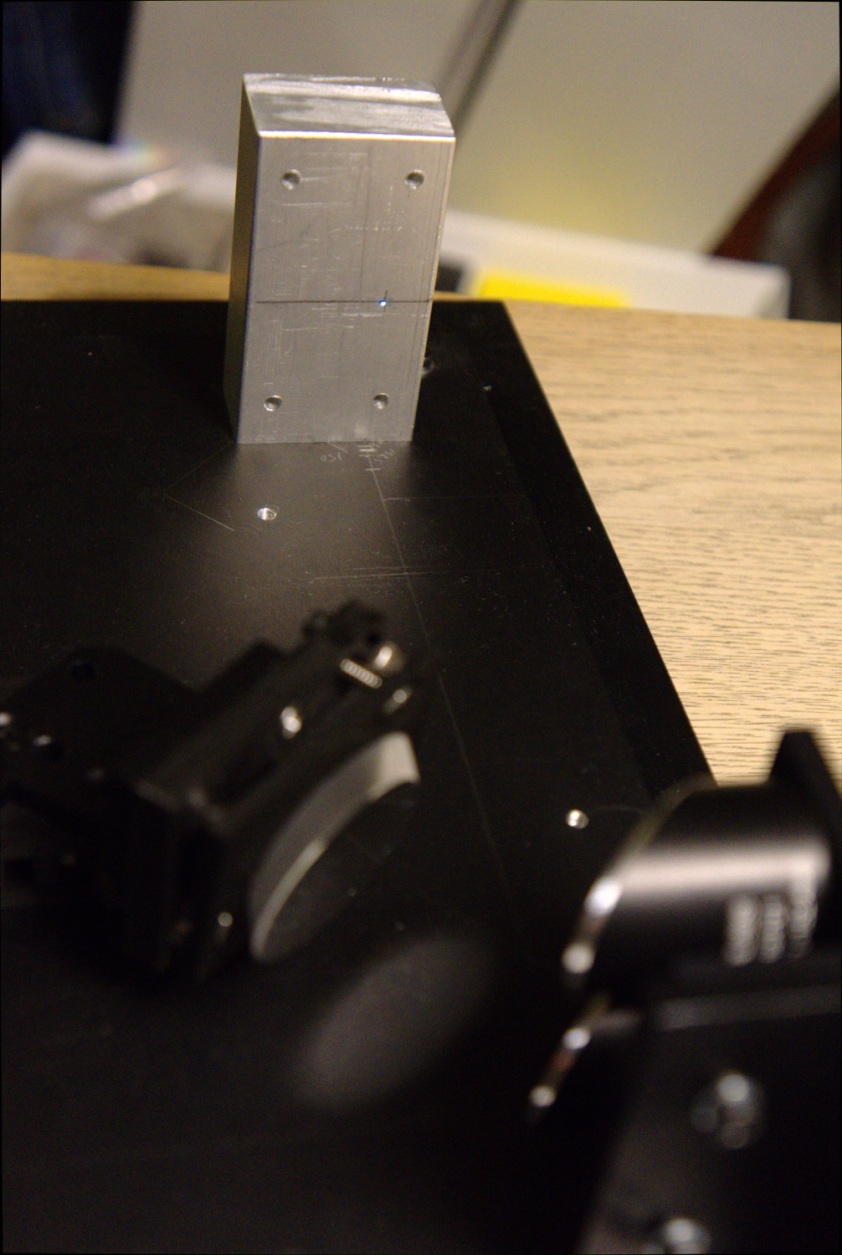

A block of aluminium with a cross to mark the height of the fiber port was placed at the focal point of P1, which was rotated until the focal point coincided with the cross. This was repeated for P2. So now I had something like this:

Two off-axis parabolic mirrors, one spot.

The two mirrors won’t stay parallel as they must be rotated so their principal axes (I’m not sure about the terminology here: the axes towards the grating) have an angle between them of 2α ie. 10.6° in my setup. This will introduce the first (small, I hope) error.

I’ve been trying to get my head around the magnitude of the error. I’m not an optical engineer, so I’ve made no attempts at further analysis than this:

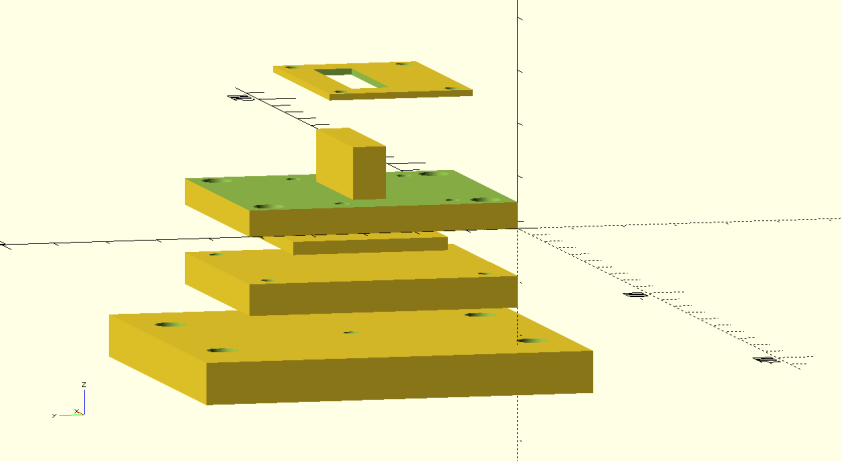

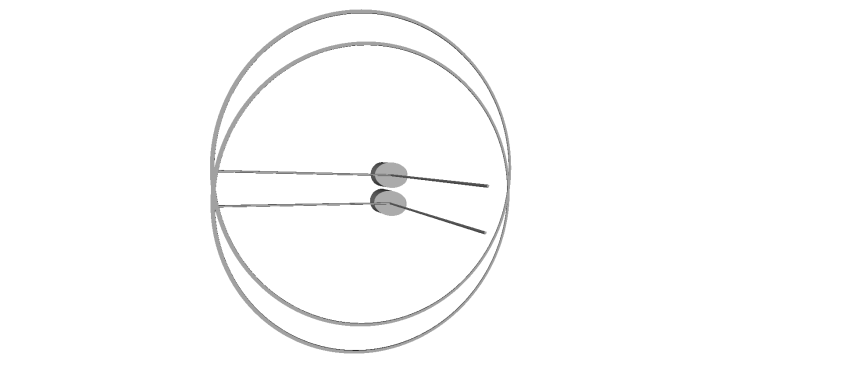

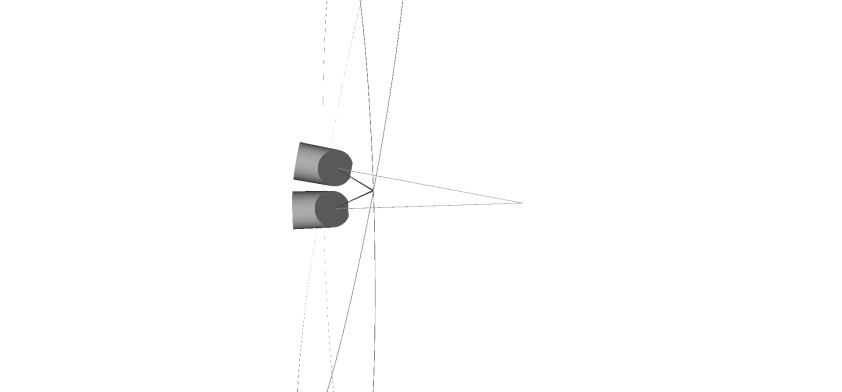

P1 and P2 before 1st adjustment. Ok, so it’s not superclear. In the center we have the two mirrors. The two lines ending in nothing are the mirrors axes towards the grating. The two lines the form the radii of the circles are the focal points of the mirrors. Btw the mirrors are 28 mm apart in the z-axis.

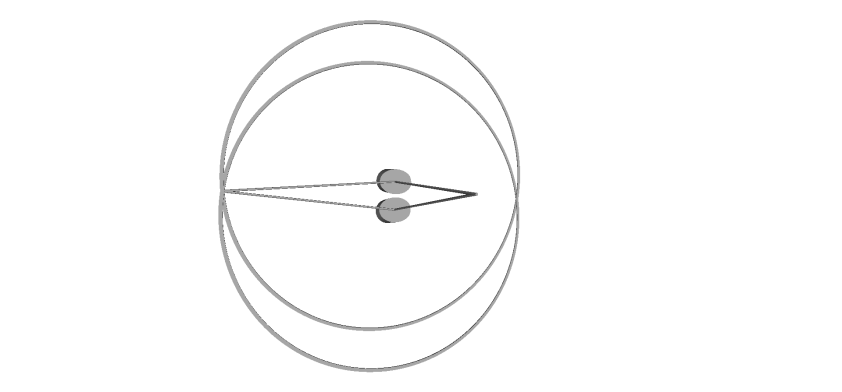

With the 1st adjustment show in the photo (two mirrors, one spot), the situation is now this:

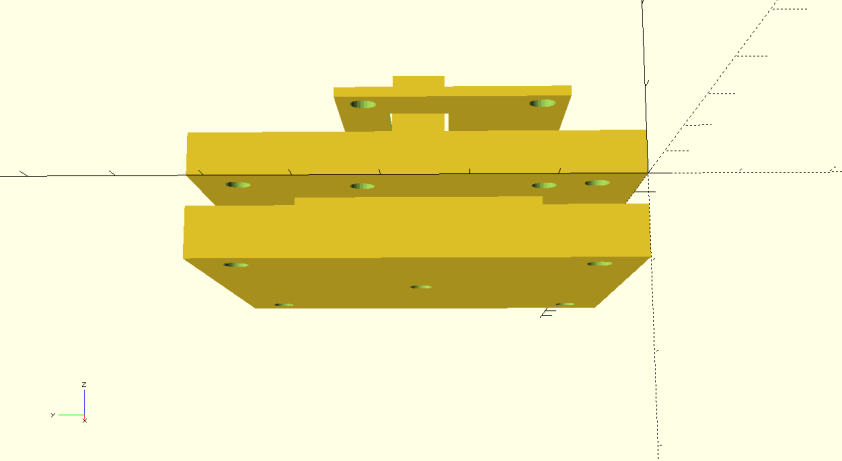

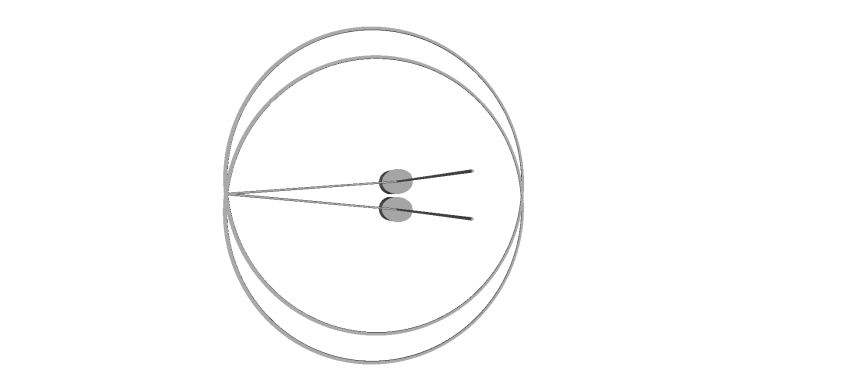

So all that’s left is to bring the end points of the two axes towards the grating meet, ie. to rotate around the axes formerly defined by the focal points:

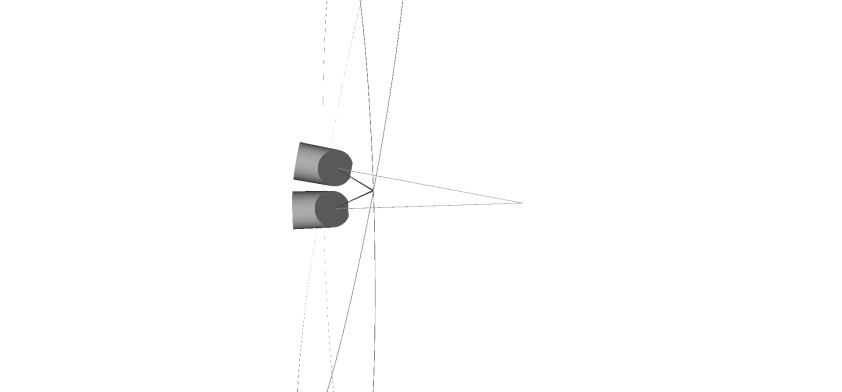

All is bliss, except that if you look at focal points from a different angle, there’s a small off-set:

hmm. Now that I’ve looked at it through the eyes of openscad, I guess there isn’t an issue, or it’s so small that it doesn’t help fretting over it. I could have sworn that on good old paper it wasn’t nothing.

I apologize for the long story (but I’m not erasing it), I’m only used to rotate molecules with my brain, not focal points and lines and circles.

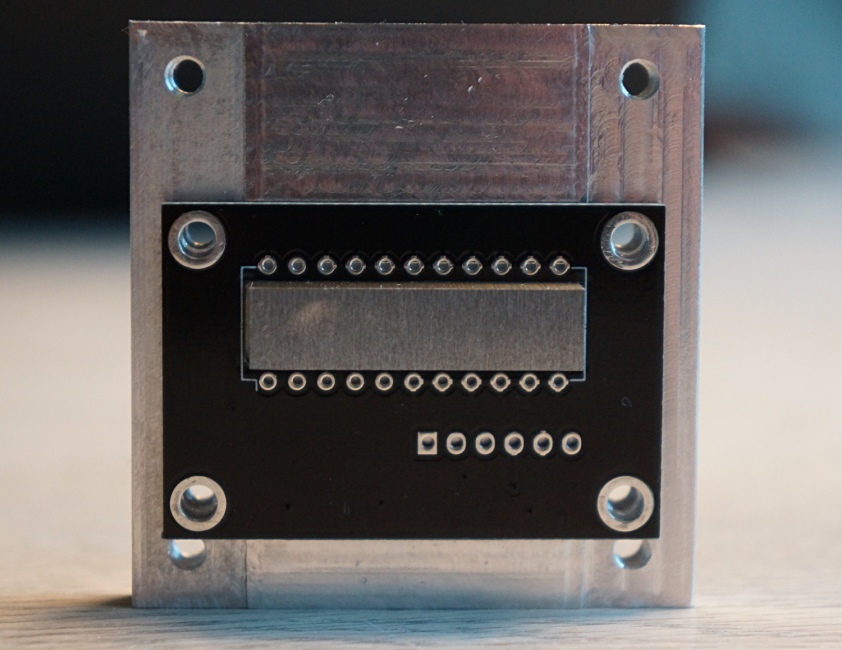

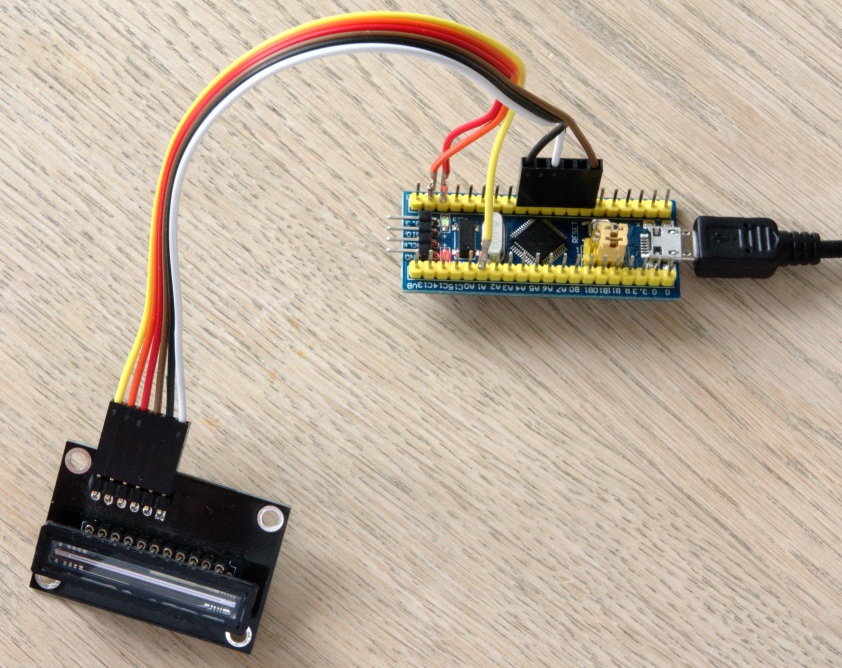

So now that that’s in order, we can procede to the next step: Installing and aligning M1 and the fiber port:

This was fairly straight-forward. I am a little concerned that I couldn’t manage getting a spot as well defined as on the aluminium target on the previous photograph.

With the fiber and M1 in place, the 2nd step for P1 and P2 was ready to be completed. Before 2nd aligment step it looks like this

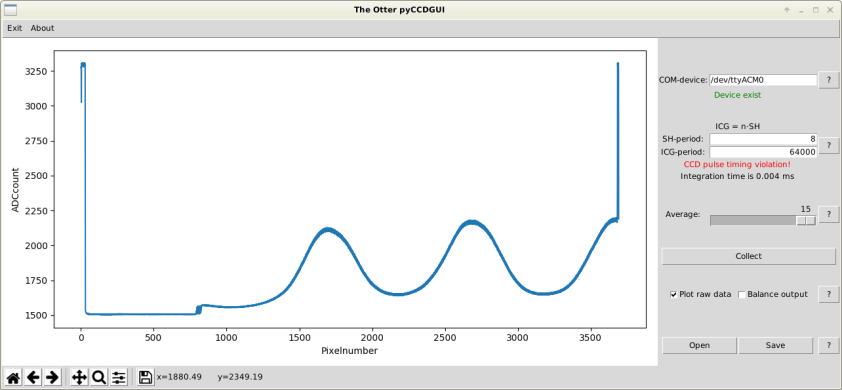

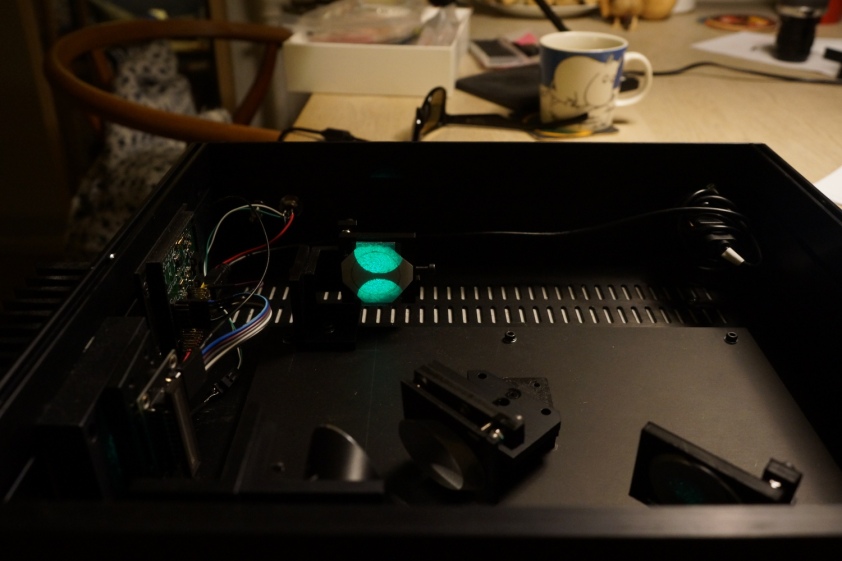

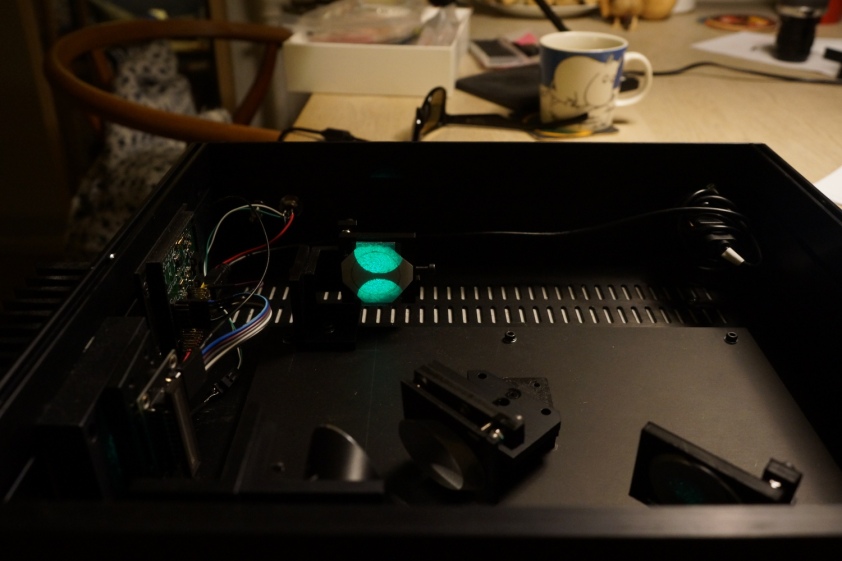

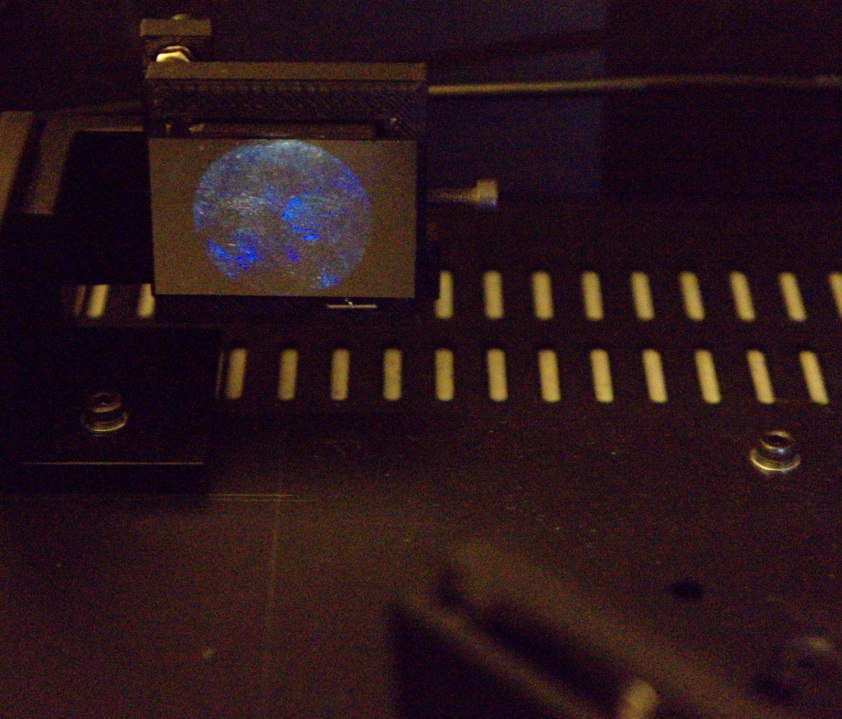

520 nm laser light from the fiber, collimated by the two off-axis parabolic mirrors and projected onto an ersatz-grating made out of paper.

Pretty cool right, but this next one has me really stoked:

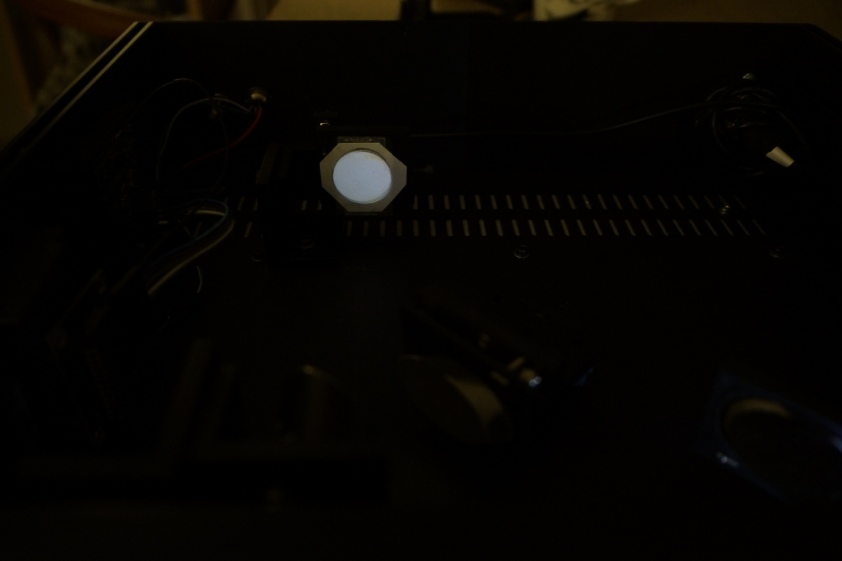

White light from a fiber, collimated by the two OAP’s and projected onto the same spot on the dummy-grating.

I never thought I would feel this way about a pale colourless circle. I’m in love. Notice how beautiful it is. It must be the most beautiful one in the whole world. Other peoples circles can just go home.

Ok, discrimination aside, the reason I’m so pleased with this, is that I’ve spent HOURS trying to get to this, but the two overlapping circles were just never very circular, leaving me with butterflyish patches of light. Btw pretty clever of nature to drug us with oxytocin, so we don’t throw away babies that were obviously riddled with beginner mistakes and just keep going until we finally get it right..

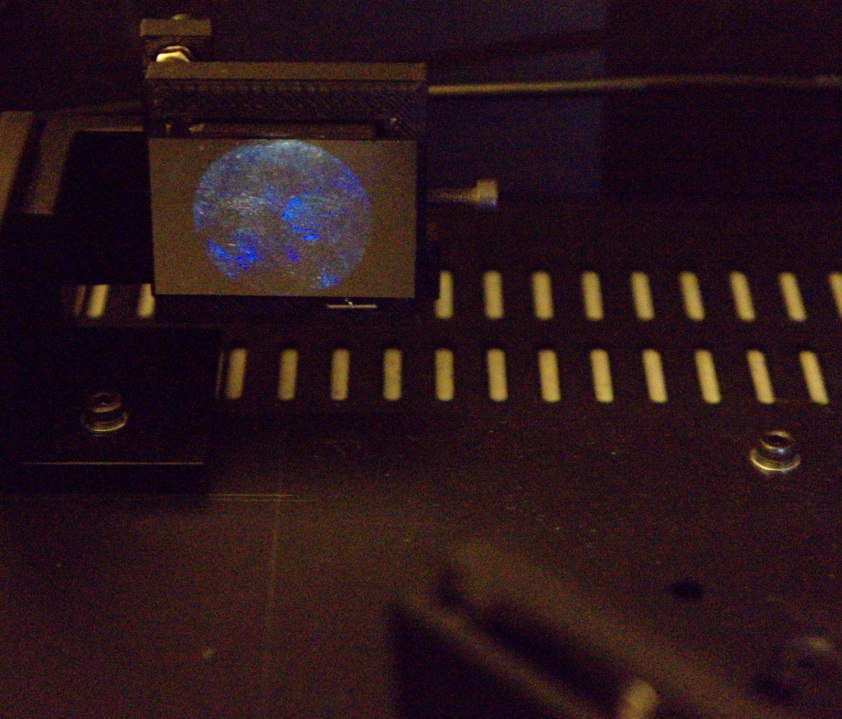

Ok, it’s obviously getting late for me. But here’s another beatiful circle. It’s my greasy fingers on a piece of glass.

I’ll post some more tmrw.